Application of energy efficiency in industry

In the economic analyses of energy consumption in an industrial plant, the calculation of energy intensity (EI) can serve as an important indicator, representing the ratio of invested energy and financial result, which is most often product value, added value or gross national income.

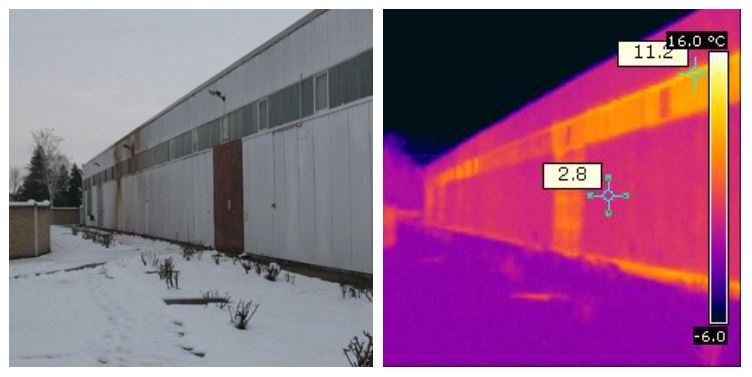

Presentation of thermal imaging for the analysis of the state of insulation and heat losses of the object in the confectionery company

With this in mind, it is clear that energy efficiency in industry is related to economic efficiency and includes technological, economic and behavioral changes. Although avoiding energy waste is a matter of personal decision, it is conditioned by having appropriate equipment for monitoring and managing energy flows, regulating the temperature in the premises and automatically turning off the lights when no one is on the business premises.

What is an energy management system?

The European Standard (EN16001) proposes an energy management system to help companies establish the systems and procedures needed to improve energy efficiency. The introduction of systematic management of energy and energy flows leads to the reduction of costs for energy sources and emissions of gases that cause the greenhouse effect.

Also, this standard defines the requirements that must be fulfilled for the company to develop and implement policies and objectives that take into account the requirements prescribed by the law. It can be applied to all types and sizes of businesses and can be adapted to different geographical, cultural and social conditions.

The company should conduct an internal review to identify areas of greatest energy consumption and opportunities for improvement. This information is the basis for establishing an energy management system, management program and goals.

The purpose of identifying energy flows is for the company to determine where large energy consumption occurs, i.e. to identify processes and equipment that affect high energy consumption, i.e. places where a change can be introduced and thereby achieve savings in energy consumption.

These are the benefits of running an energy management:

* Reduction in energy consumption – gas, oil, electricity, etc.,

* The possibility of using new technologies for energy recovery,

* Raising awareness and motivation among employees,

* Expanding and improving process monitoring techniques,

* Establishing and implementing new procedures, ways of working, etc.

The flow of energy fluids within the company and the energy efficiency of various processes and operations cannot be easily defined. This information is essential to define energy-saving opportunities. A tool that can help overcome this problem is an energy audit.

What is an energy audit?

An energy audit is a procedure that helps us define the way energy is used and consumed, and it can help us to:

* determine the energy intensity,

* rate the energy efficiency,

* identify opportunities and proposals for energy saving,

* establish an implementation plan for the energy-saving project.

A standard energy audit of an industrial plant is a complex task. It requires the engagement of professionals from various fields, including mechanical engineers, electrical engineers, civil engineers, architects, specialists in lighting and electronics systems and others. The energy auditor (consultant) must have experience with the processes taking place in the plant, as well as knowledge about the supply and distribution of various forms of energy in the form of heat and electricity. He should additionally have basic knowledge in the field of finance. This is necessary for the financial evaluation of various energy-saving proposals that will result from the energy audit.

How much can be saved by increasing energy efficiency in industrial systems?

To see the possible level of savings, see the following example of comparative energy costs for uninsulated and insulated piping.

If steam from the boiler is transported through an uninsulated pipeline with a diameter of 150 mm to a consumer with a capacity of 1500 kW, which is 100 m away from the boiler, the heat loss is 1.5 kW/m. Energy costs calculated based on the price of natural gas according to data from 2017 (including the degree of usefulness in the amount of 77.27 per cent) amounted to 5,368 RSD/kWh.

Annual energy costs for consumers are:

1500 kW x 7200 h/year x 5,368 RSD/kWh = 57,974,400.00 RSD

If the pipeline is insulated with mineral wool, heat loss is reduced from 1.5 kW/m to 60 W/m. The annual energy costs for consumers (including the degree of usefulness in the amount of 84.66 per cent) amount to:

1500 kW x 7200 h/year x 4,899 RSD/kWh = 52,909,200.00 RSD

Annual savings amount to: 5,065,200.00 RSD.

Advantages of using heat pumps in the food industry

With the introduction of stricter standards to increase the energy efficiency of industrial plants and preserve the environment, a greater use of heat pumps is expected compared to the current situation in the economy (for example, at the world level, the largest representation of industrial heat pumps is in the USA and France).

These are just some of the advantages of using heat pumps in the industry:

– Savings in energy consumption amount to 15-30 per cent, and in some cases more than 50 per cent;

– Reducing total operating costs;

– Reducing the consumption of fossil fuels, preserving their natural reserves and reducing the emission of harmful gases;

– Increasing the working capacity of certain devices, such as evaporators and dryers;

– They take up significantly less space compared to other energy supply systems;

– Reducing investment and operating costs in plants where it is necessary to achieve the simultaneous cooling of one and heating of another process fluid.

Why is it important to entrust the introduction of energy efficiency measures to experienced professionals?

To achieve the greatest possible benefit from the introduction of energy efficiency measures, you need to entrust the implementation of the energy audit and the preparation of a feasibility study to a company with significant experience and top references in the following areas:

* Energy efficiency

* Process optimization

* Energy comparative statistics

* Introduction of an energy management system in accordance with EN 16001

* Creation of Conceptual Design and Main Projects for power plants

* Implementation of renewable energy sources and cogeneration plants

* Conducting training for engineers dealing with energy and energy flows in industrial enterprises

* Energy reviews, analyses and studies concerning the introduction of energy efficiency measures in the sectors of final energy consumption.

If you need advice regarding introducing energy efficiency measures, feel free to write to us at info@energetskiportal.rs , and we will do our best to get a response from our associates, who are excellent experts in this field, as soon as possible.

Useful link:

Ministry of Construction, Transport and Infrastructure